In the rapidly evolving Direct-to-Film (DTF) printing sector, accurate heat press time and temperature are paramount to ensuring the quality and durability of the final product. KongKim, a leading supplier of DTF materials, today released its official heat press guide for its DTF cold peel film and hot peel film, aiming to help users achieve excellent transfer results and thus enhance the market competitiveness of custom apparel and promotional items.

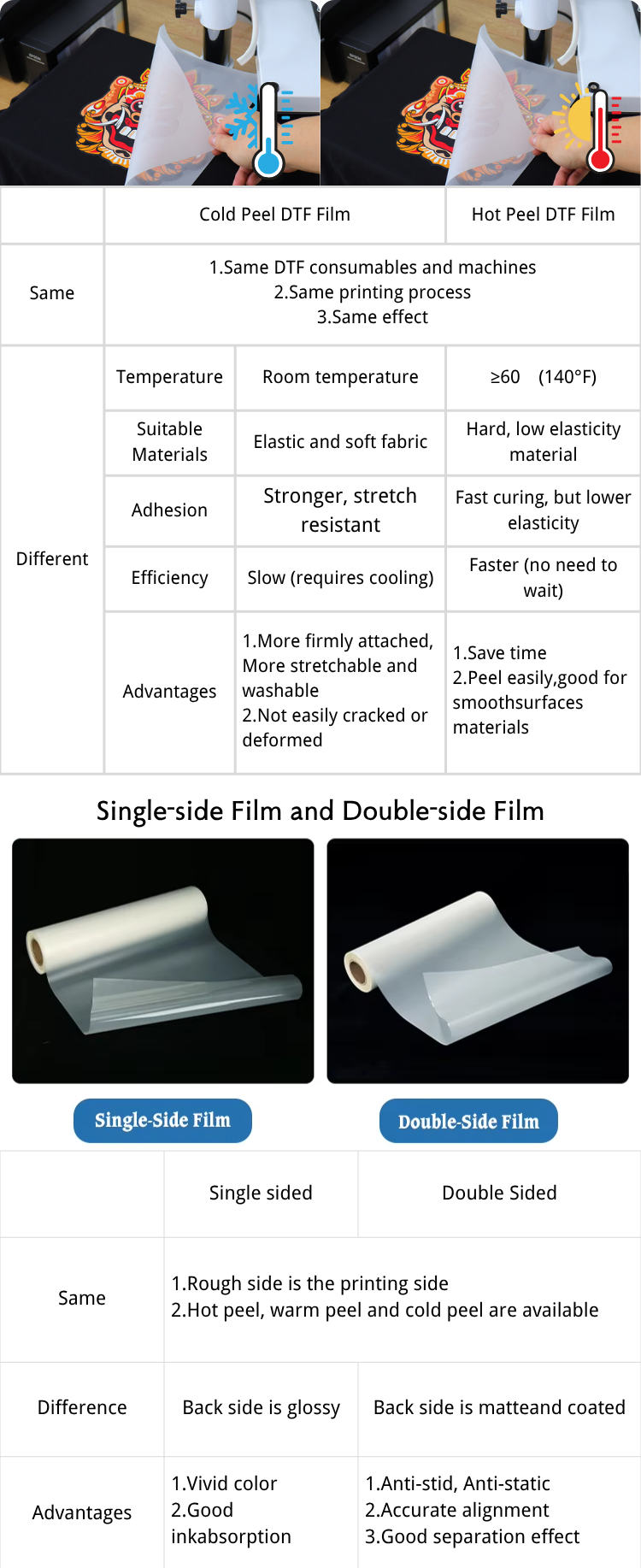

DTF technology is widely popular for its ability to produce high-quality, full-color prints on a variety of fabrics. However, many users often find themselves uncertain about the optimal heat press parameters. KongKim emphasizes that understanding the characteristics of different DTF film types and following correct operational steps is crucial to avoiding common transfer issues such as poor adhesion, dull colors, or film residue.

KongKim DTF Film Heat Press Guide:

1. KongKim DTF Cold Film:

Pressing Time: Approximately 10-15 seconds.

Temperature: Maintain between 160-180 degrees Celsius.

Key Operation: After the heat press is complete, it is essential to wait for the film to cool down completely before peeling. Cold peeling ensures optimal ink fusion with the fabric, resulting in sharp, crisp image edges and preventing residue or distortion. This characteristic makes it ideal for applications demanding ultimate clarity and fine detail.

2. KongKim DTF Hot Film:

Pressing Time: Typically similar to the initial pressing time for cold peel film, conducted at 160-180 degrees Celsius.

Key Operation: The film can be peeled directly or immediately while still warm after the heat press is finished. The convenience of hot peel film lies in its instant nature, significantly boosting production efficiency, especially suitable for high-volume or speed-sensitive production environments. Despite the faster operation, KongKim’s hot peel film still offers excellent adhesion and washability.

“We understand that users want to maximize the efficiency and quality of their DTF prints,” said a KongKim Product Manager. “Both our 30cm 60cm cold peel and hot peel films are meticulously designed to deliver outstanding transfer results. The key is to precisely control the heat press time and temperature, and follow the correct peeling method, based on the type of DTF film you are using. Operating within the recommended temperature range of 160-180 degrees Celsius will ensure our DTF films display their best color vibrancy and long-lasting durability.”

Proper DTF heat press technique not only guarantees strong image adhesion and vibrant colors but also significantly enhances the print’s washability and resistance to abrasion, thereby providing customers with higher-value custom products. KongKim encourages all users to follow these official guidelines to fully unleash the potential of their 12 24 inch DTF films and drive success for their businesses.

About KongKim: KongKim is a leading global supplier of printing equipment and consumables, dedicated to providing innovative, high-performance, and reliable solutions for the digital printing industry. With a deep understanding of technology and customer needs, KongKim continuously introduces products that meet the forefront of market development.

Post time: Jul-24-2025